CUSTOMER PROJECTS

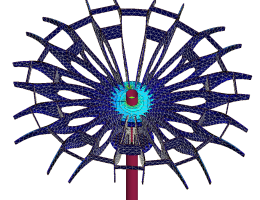

TAPIRUS PROJECT - ELECTRIC CHARGING STATION

BRNO, CZECH REPUBLICH

Structural Designer:

Parametric Designer:

Year:

PROJECT DESCRIPTION

PROJECT DESCRIPTION

Location: Brno, Czech Republic / Date: 2023

Structural design: Michna&Perháč

Parametric design: Parametr Studio

Manufacture: Vesper Homes

3d printing: ICE Industrial Services

Client: Festival architektury

Introduction

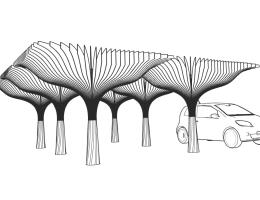

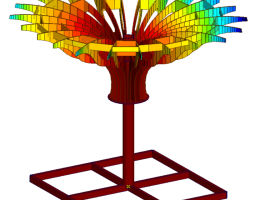

The project started with a request from the fair “Festival architektury” organizers to introduce the electric charging station of the future. Within 3 months from the assignment to installation with a zero budget, the intention was to present a starting prototype representing a manifesto for other models of charging stations in the cities of the future. The initial requirements for the project were a hybrid structure of steel, 3D-printed concrete, and wood. A necessary condition was the ability to assemble units in a modular system. Energy should be obtained concerning ecology from solar radiation. Design and production technologies are closely linked to sustainability.

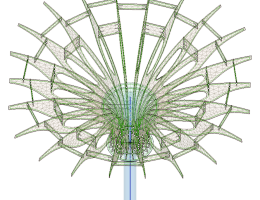

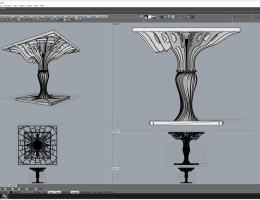

Parametric design:

From the beginning of the assignment, the project was created as a parametric script. The program was gradually supplemented and adapted to new needs. The script was edited and optimized in real-time based on feedback from the production company or static calculations. Thanks to this, it was possible to verify and constantly adjust a large number of variants and requirements in a very short time and thus complete the project properly.

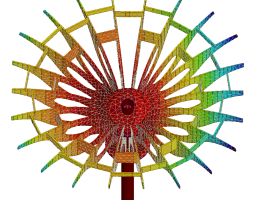

Structural analysis:

AXISVM software was used for structural analysis. Thanks to this software, we were able to determine the requirements for the basic parameters of the structure in terms of load in a very short response time. The values from the calculation were immediately returned to the parametric model, which generated again a new version of the 3D data for the analysis application. In the next step, we would like to connect AXISVM with the Grasshopper environment (visual algorithmic editor) without needing to export the model. Our goal would be to create direct static response connectivity that would immediately show us the effectiveness of using the structure and thus further strengthen the significance of the entire parametric model.

Manufacturing:

During fabrication, no printed form of documentation was created for production. A digital 3D model served as fabrication data. The plywood parts were made with a CNC machine and the concrete column with a 3D printer. The net production time was the shortest part of the project. Hundreds of hours in design resulted in units to tens of hours of individual parts.

Conclusion:

The project was presented at the Czech construction fair in Brno and in the future could be used in larger quantities to supply electric means of transport in the city.