CUSTOMER PROJECTS

Public Hall Tbilisi

TBILISI, GEORGIA

Structural Designer:

Architect:

Year:

MTM Kft. , STEELXPERT Kft.

Massimiliano and Doriana Fuksas

2020

PROJECT DESCRIPTION

Introduction

The architectural concept of the building is a scattered layout multi-storey office building covered with 11 freeform roof units (‘petals’), which are mainly supported by ‘tree-like’ branching pillars and partially by the building frame.

During the construction phase, several companies exchanged, resulting in very poor structural quality and performance. The structural issues of the Petals are classified as follows:

- geometric parameter inconsistencies

- deviation from the design geometry

The client became aware of the majority of the structural problems and ordered a thorough structural investigation and corresponding repairing/strengthening works and commissioned MTM Ltd. with the following structural engineering tasks:

- global structural analysis of the existing steel structure and verification of its strength against various design situations through its intended design life

- in case of any structural integrity issues, the development of detailed strengthening methodology and to supply the construction plan package

Analysis methodology

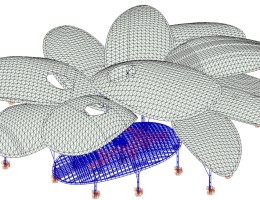

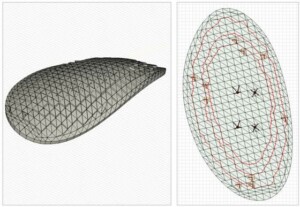

All petal roofs have the same framing concept, i.e. orthogonal freeform truss girders that are vertically lined. Layout distance between framing raster is either 1m- or 2m on center. Since the petals are not separated from each other (many of them share common column branches, aka. ’pillars’), it was soon realized that none of the petals, can be investigated separately by itself (e.g. in a submodel) without falsifying the dynamic behavior of the system.

Predesign analysis also resulted that it was not feasible to include all structural members of all petals in the Finite Element Model. Thus reduction of Degrees of Freedom (DOF) of structural members, which were not our main interest, was needed. As a result, we developed a methodology where the truss system of the petals (other than our main interest) was substituted with equivalent Shell Finite Elements with a rough mesh.

The equivalent shell system is carefully chosen and fine-tuned to keep the most important dynamic features (mass, stiffness) of the original truss system.

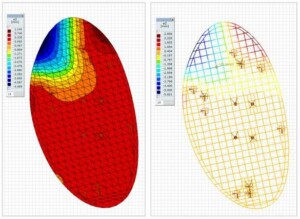

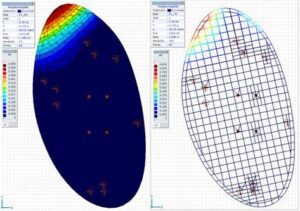

Depending on the shape of a petal, we usually used 4-5 representative shell thicknesses to approximate the original frame structure – see the next figure.

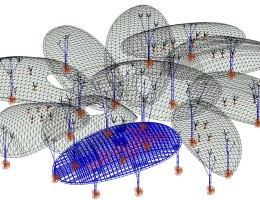

Shell representation submodels were then calibrated against space frame models by using unit- concentrated test loads at boundaries while checking the deflection at that point – see below figure.

In order to get the required compliance of the dynamic behavior between the space frame vs. shell representation models, vibration analysis of both model types was needed. The goal was to have compliance at least in the 1st eigenvalue mode shape results and the directional modal masses compatible – see next figure.

Further calibration of distributed masses and a couple of needed in order to achieve satisfactory convergence.

As a control to harmonic response analysis, we also used the more sophisticated time history (dynamic) analysis to better understand the dynamic behaviour of the structure, thus localising areas of potential structural problems.

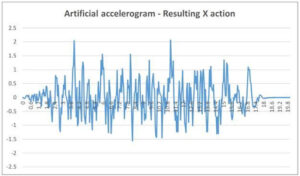

In the lack of sufficient information on site-specific accelerograms recorded in the Tbilisi area, the description of the seismic motion is made by using artificial accelerograms. For the purpose of the dynamic analysis (6), different accelerograms (3 for global X- and 3 for Y-direction) were artificially generated that comply with the rules specified in EN 1998-1 Sec. 3.2.3.1.2. – see next figure for a sample of the accelerograms used.

Strengthening method

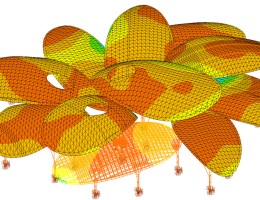

ULS check of existing frame members and the full dynamic time-history analysis (THA) pointed out the weakness of the original design concept and helped to develop the provided strengthening solution.

While developing the strengthening methodology we focused on the following goals:

- same framing methodology all over throughout the petals

- assembly/connection types should be uniform

- number of strengthening should be kept as few as required

- site work (cutting, welding, protective surface coat recreation) should be minimized

- the method should be adaptable for possible strengthening of other problematic petals

After establishing the above goals, an iterative ‘trial-and-error’ design procedure started. Main steps of the iteration loop:

- strengthening members are implemented in positions where the highest bending moments in the tangential plane of the top/bottom chords of the existing structure arisen

- analyzing the overall structural model with the updated strengthening members and verifying the member strength in ULS and Seismic design situations

- in case there are still excessive moments in the members of the existing structure, or the previously applied strengthening members are not sufficient in their strength then we need to go back to step I. by:

- applying more strengthening members to reduce the excessive ‘membrane’ forces within the petal, and/or

- fine-tuning the adequate strengthening member profile

In less than (4) consecutive runs we managed to reduce the unwanted excessive membrane deformations and corresponding forces within Petal No. 4. The provided strengthening solution helps to redistribute the membrane forces with the help of properly designed and placed diagonal bracings in the case of medium or more severe earthquakes. It is also helpful in reducing the internal forces in the welded joints of the existing structure against the effect of gravitational and climatic loads in persistent ultimate state design situations.

Modelling and analysing with AxisVM:

- by substituting the petals that were outside our interest with equivalent shell models, AxisVM helped to radically reduce the computational resources needed, yet helped

- user-defined stiffness matrix for shell FEAs gave us the possibility to adequately scale the equivalent substituting model for petal roofs outside our interest

- time-history analysis made it possible for us to adequately catch the dynamic behaviour of the such irregular structure